So, a few months ago I bought the badass THRUSTMASTER T500 RS racing wheel which basically costs like twice as much as a playstation 3.

It quickly became obvious that a piece of hardware like this requires a setup to do it justice, so I started investigating racing seat options.

After lots of browsing it also became obvious that the price and quality of the many available steering wheel cockpits was totally unacceptable.

Most of the good ones are manufactured overseas, cost upwards of $1500, and even then there was no guarantee that the wheel would mount well and the seating dimensions would be perfect (at those prices, it had better be damn perfect).

If I went below the ~$1000 threshold, the engineering of the products was generally crap city, with asinine designs like a pole sitting in between your legs and a chassis that had unacceptable levels of flexing and rattling.

Totally lame.

So the only option left was to build a chassis myself.

Enlisting the woodworking talents of my friend Bruce C.,

we set out to make a chassis ourselves with the following goals:

1. Recreate the exact seating geometry from my E46 M3.

2. Super rigidity and stability.

3. Don't spend $1500.

4. Be able to remove the nerd device from my living room at select times so as not to interfere with girl seduction schemes.

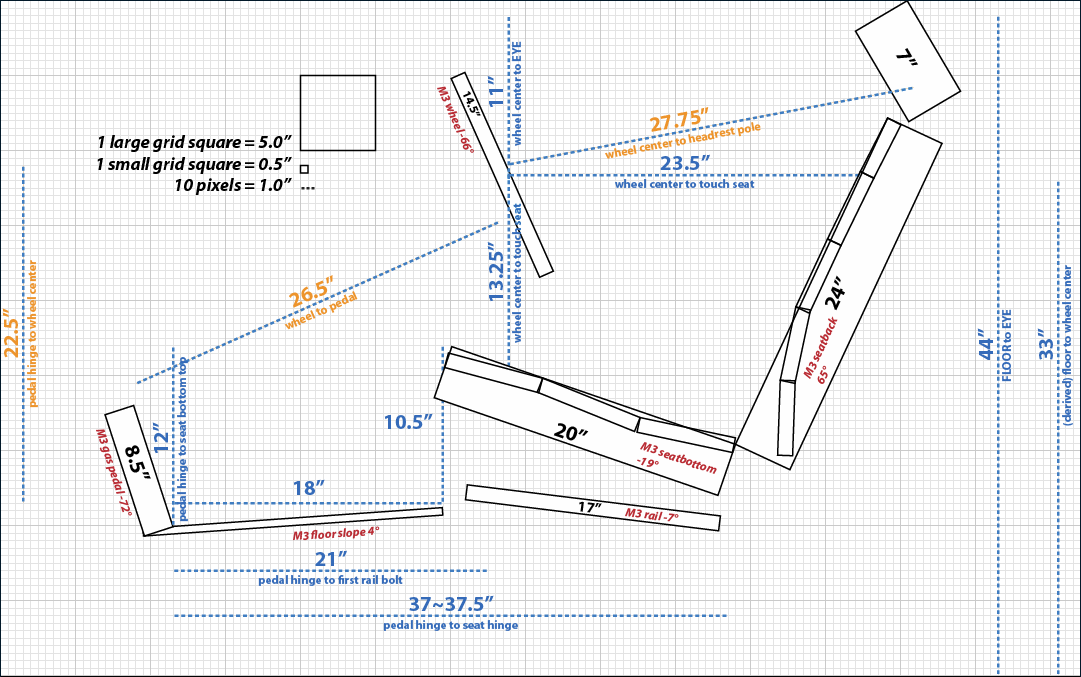

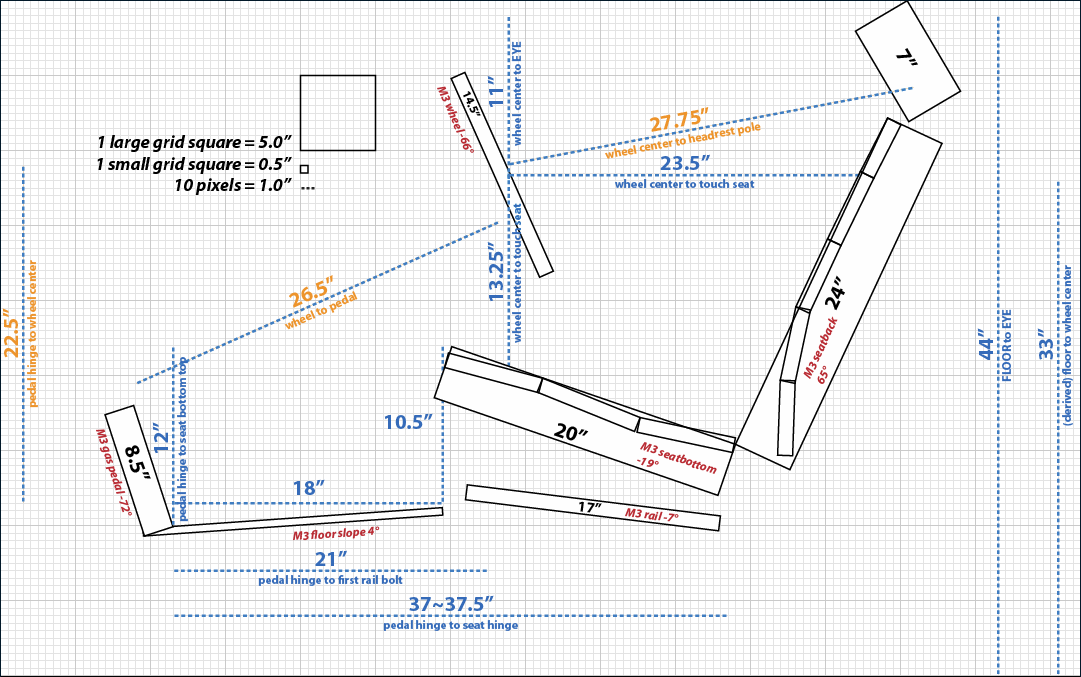

First, I drew up a plan that represented the current precise geometry of my seating position in my car:

Next, I obtained an E36 seat for free from JimsR on this forum.

The seat was dirty as hell, but after cleaning and cleaning and leatheriqueing over about two weeks the result was quite good.

I removed the dirty net from the backrest and sawed off the seat belt thingy:

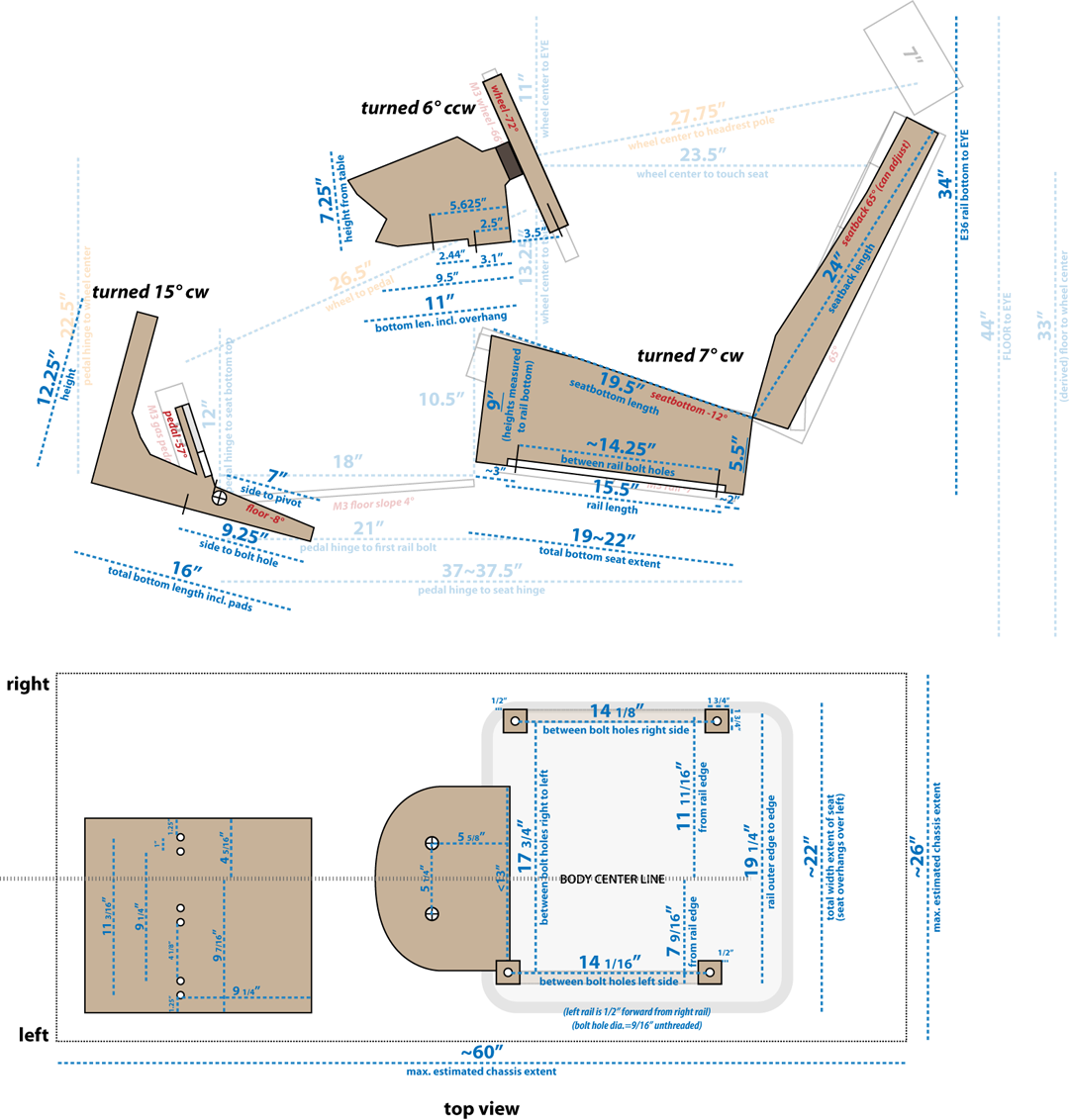

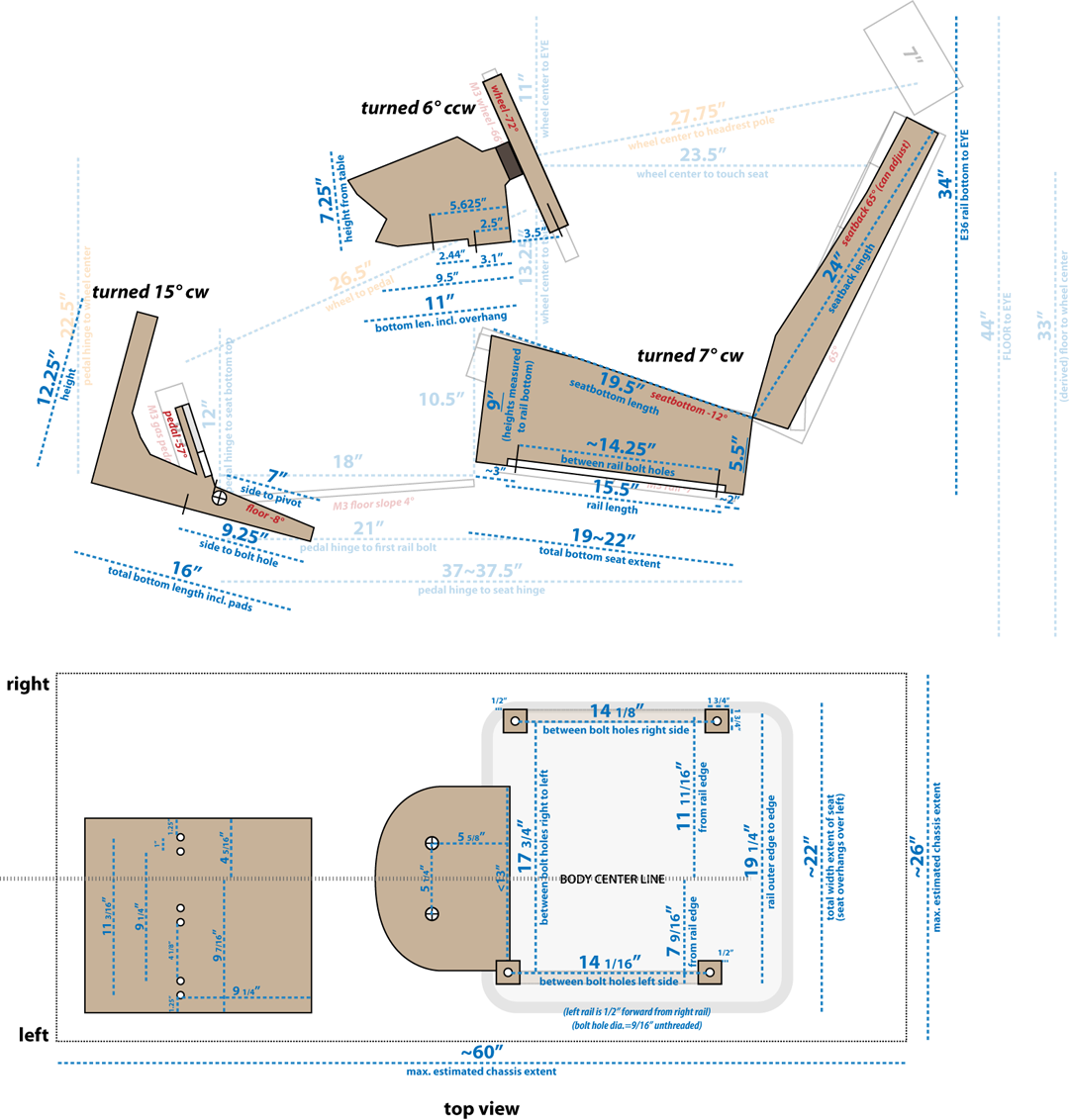

It just so turned out the the E36 seat was actually very close in dimension to my M3 seats. Here, I have taken measurements of the E36 seat, the T500 wheel and pedals, and overlaid them on top of my original geometry sketch:

It just so turned out that the E36's seat was very close in dimension to my car seat setup, but in order to make the manual E36 seat match the exact same angle, we would have to mount this seat at a 7 degree incline. Here is Bruce measuring the wooden rails that we will bolt the seat rails onto:

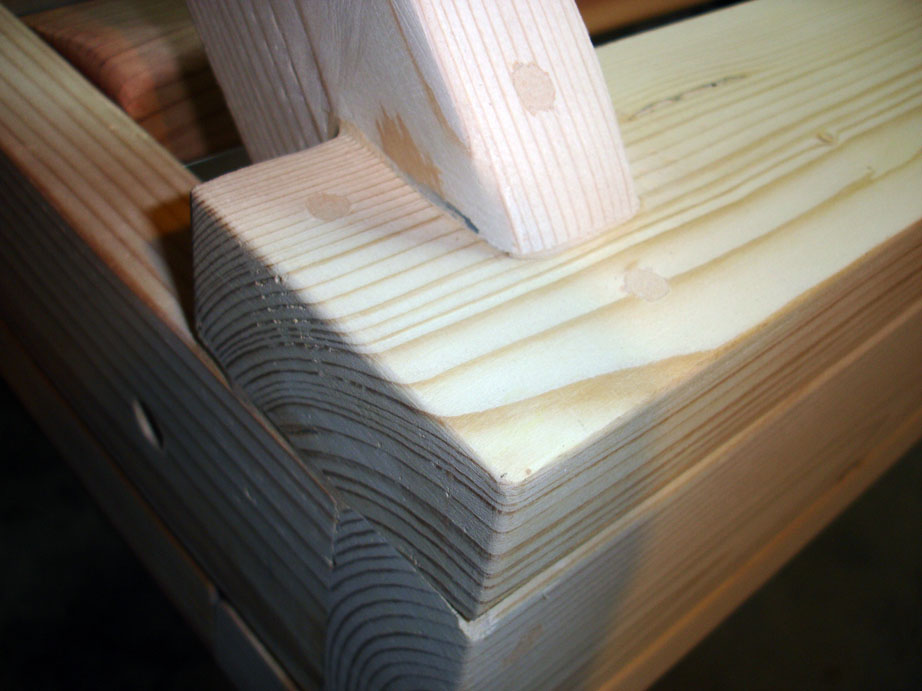

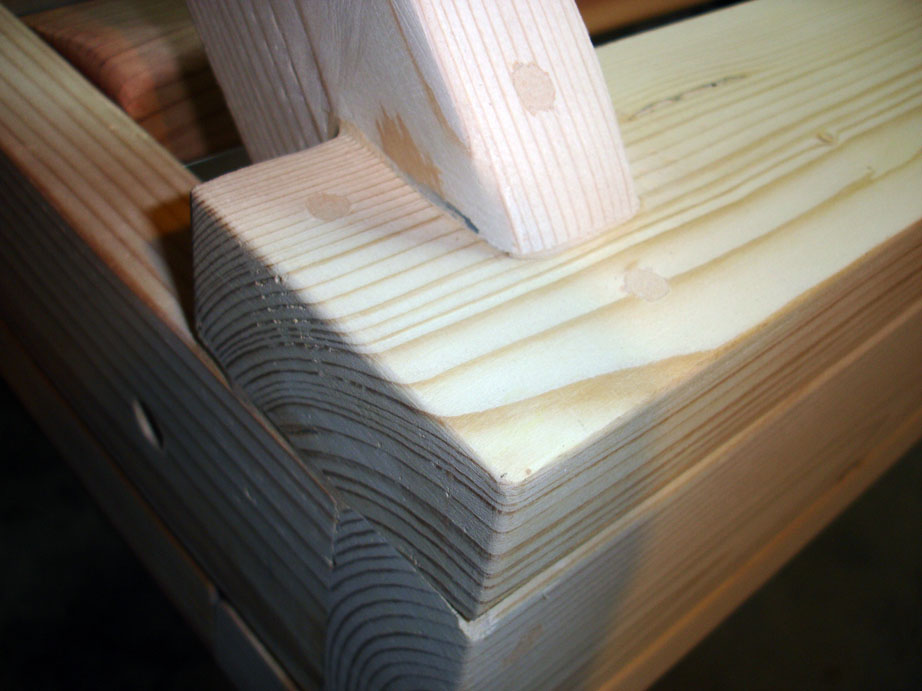

Now, in order to simplify some of the construction we planned to drill a hole through a wooden rail, and mount the seat rails to the wooden rail using tee nuts, which are nice fasteners that are hammered into wood on one end, and have a threaded hole for a bolt to go through.

It turned out that the bolt size of the seat rail was M12, but after calling numerous vendors that specialized in "hard to find" and "metric" fasteners it was just impossible to get tee nuts in that size. So, I ended up boring out the seat rail holes to 1/2" with a dremel, which was actually quite easy and only required about 0.7mm of boring. Here you can see the wooden rail attached to the seat bolt, the tee nuts with 1/2" bolts threaded through them are facing the camera:

Here is the seat with the posts fastened, with my angle locator on top verifying that the bottom surface is at the exact desired angle:

Next, we built a box around the posts, centered about the seating position, which was a bit tricky because the seat itself is not at all in the center of the rails:

Some time shortly before this point, we decided to engineer the construction in two modular parts which we would later fasten together, so that the chassis can be broken down and moved relatively easily. Hopefully this will not compromise the rigidity of the final structure.

Next, we started building the front component which will house the steering wheel and pedals. The dimensions of the T500 wheel were just different enough to make its exact position unclear, so we built two supports deliberately higher than we need to, so we can test-fit the mounting surface of the wheel first before we finalize the position. Clearance for the legs is also a concern. By the way, the steering wheel's mounting surface needs to be rotated by 6 degrees to match the angle of my car's wheel:

progress update!

Here are the two main components built so far:

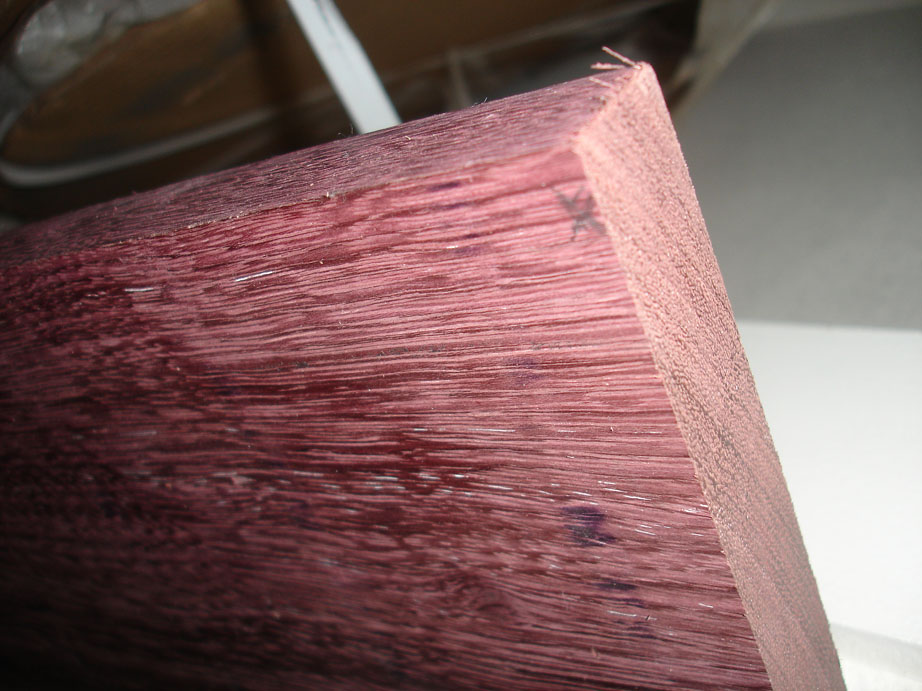

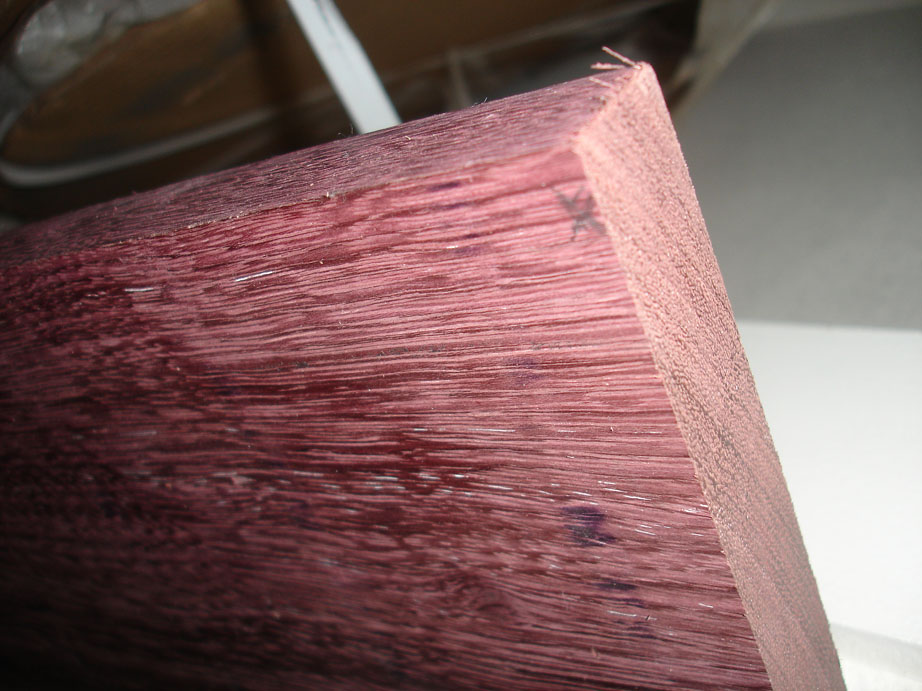

There is a store called Rockler that sells all kinds of exotic materials, I procured this piece of hardwood called Purpleheart which will serve as the main platform. It is super dense and heavy, and purple:

Test fitting the purpleheart. The platform surface is angled so that the final wheel angle will match the angle of my steering wheel in my car:

The purpleheart is now bolted to the main frame by four 1/2" bolts. The wheel is now also bolted into position and we are test fitting the pedal position:

We have finalized the location of the pedals and are now attaching the pedal mount to the frame. You can also see here the metal brackets we installed under the platform arch for extra stability:

What's left?

- finish/clean up the purpleheart piece.

- extra support around the wheel attach surfaces for even more stability

- possibly enclose the pedal area.

- possibly install a floor.

- attach the two modular pieces together

- install the giant and super heavy duty rubber feet

- sand, stain and finish wood surfaces #19:

*4/17 UPDATE #2* Ara's Video Game Racing Chassis Build Author: nasrudin,  Posted: Sun Apr 17, 2011 5:39 pm

Posted: Sun Apr 17, 2011 5:39 pm

----

progress update #2:

Since the wheel will be hanging over the purpleheart piece and we expect it to be subject to forces in several directions, we have cut some additional strips of the purpleheart and attched them with the grain perpendicular along the sides of the wheel platform in order to further strengthen it in the longitudinal direction:

Here we add diagonal structural members- as is the wheel platform is definitely not rigid enough without them:

Here are the beginnings of the side-rail assembly which will join the front and rear components. For easy disassembly, these are 1/2"x3" wing bolts with crazy large washers, attached to tee nuts on the opposite sides. I was concerned that this approach would not net suitably rigid results, but even after just completing the rear side and clamping the front parts it feels very promising:

Here is a full view of the chassis, there are four wing bolts holding the rear section in place and we plan to add four more in a similar way for the front piece.

We are also test-fitting the four large 2"x2"x16" rubber guards which I am repurposing as feet for the assembly. The feet are completely made from rubber with a hardness comparable to that of a tire. Even without these pieces properly attached it's feeling good and stable, with no signs of flex or movement no matter how I lean in the seat.

almost done, maybe a couple more sessions left. #20:

!5/2 UPDATE #3! Ara's Video Game Racing Chassis Build Author: nasrudin,  Posted: Mon May 02, 2011 9:30 am

Posted: Mon May 02, 2011 9:30 am

----

Update #3:

fastening the giant rubber feet:

Now basic construction is complete. Here is Bruce testing out the chassis:

After sanding and sanding and filling the screw holes:

Prep for wood staining:

Here is a test stain block with two coats of cherry wood stain:

Staining the ugly underside of the seat piece:

more will be coming. #21:

FINAL UPDATE Ara's Video Game Racing Chassis Build Author: nasrudin,  Posted: Sat May 21, 2011 11:01 am

Posted: Sat May 21, 2011 11:01 am

----

Final Update!!

The front section, halfway through the staining process. I'm using one coat of prestain and two coats of cherry oil based stain.

Here is the front section with one coat of stain applied:

Close-up of the purpleheart piece after sanding complete. This piece will not be stained but needs a few coats of topcoat:

The rear section, fully finished. Three coats of topcoat are on the wood here:

The finished purpleheart piece. Nice and smooth and shiny:

The side rails, fully finished:

The front section, nearly fully finished. I've added a small bit of carpet in the area where your feet go. The only bit left on this one is to add two aluminum L brackets to reinforce the wood posts to 11:

We signed the front piece with a wood burning pen:

Now that everything is done, it's time for final assembly. Here I'm bolting in the pedals:

Bolting the steering wheel to the purpleheart platform:

All four components laid out and ready for fastening. The rails can be fastened by hand since we use wing bolts and tee nuts. Notice the aluminum brackets are now also on the front section:

Now the purpleheart piece bolts on top of the front section. All done and ready for action:

Side front view:

Side side view:

Side top view:

Rear view:

Side rear view:

Nighttime view:

I can hardly believe its done. The chassis is rock solid and wheel and pedal placement feels fantastic.

Κάποιοι έχουν κάνει ηδη παρόμοιες κατασκευές (VanVIC

), απλά εδώ ο φίλος το έχει πάει σε άλλο εντελώς επίπεδο, προσομοιώνοντας ακριβώς τις διαστάσεις της θέσης οδήγησης ενός Ε46

Posted: Sun Apr 17, 2011 5:39 pm

Posted: Mon May 02, 2011 9:30 am

Posted: Sat May 21, 2011 11:01 am

Απάντηση με παράθεση

Απάντηση με παράθεση